CNC Machining Service

Leading Precision CNC Machining Service-OEM/ODM China CNC Machining/Machined Parts Manufacturer

Do you need a reliable CNC Machining partner with unparalleled quality? Modest (Taizhou) International Trade Co., Ltd. is a professional and experienced China CNC company provides precision CNC machining service with advanced machines and skilled engineers.Our main production machines are imported from Switzerland,Japan and America and all our engineers own rich experience in CNC machining operation. They are always able to find the best way to produce the highest quality CNC machined parts with the lowest cost for customers.

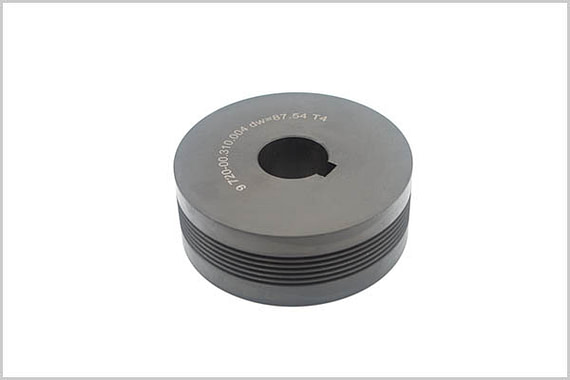

With strong capabilities and years of rich experiences, we can provide top-ranking but cheap custom CNC machining services including 3/4/5 axis CNC milling service, rapid prototyping service, and precision CNC turning service. Our high-quality rapid CNC machined products are involved in the field of Automation industry, Wind/Solar energy, Automobile parts machining, Textile machines, Medical equipment, Packing machines, Led lighting industry, etc.

Modest Precision CNC Machining Capabilities and Features:

- Over 10 years of experiences and know-how in CNC machining services, Modest mainly provides OEM/ODM CNC machining service and related metal machining services including Grinding, Laser cutting, Diecasting, 3D printing, etc.

- Support low, medium to high volume batches production.

- Rapid prototyping and end-use manufacturing.

- High dimensional accuracy, high speed productivity and high reliability.

- Wide range of optional metal and plastics materials.

- Strong productivity and fast delivery time.

- Required finishes and tight tolerances are available.

- More than 100 sets of advanced CNC machining machines in Modest.

| Equipment Name | Equipment Type | Place of origin | Quantity |

| 5-axis milling center | MAZAK-VARIAXIS C-600 | Japan | 5 |

| 4-axis milling center | INTEGREX J200S, etc | Japan, Switzerland, German | 18 |

| 3-axis milling center | AMS-MCV-450-BT40, etc | Switzerland, America, China | 33 |

| CNC Turning center | I5TE, CK7520A | China | 35 |

| Turn-milling center |

TSUGAMI B0205 |

Japan | 12 |

| Surface Grinder | M7130H | China | 3 |

| Cylindrical Grinder | M11200 Cylindrical | China | 5 |

| Laser marking center | LSF20N | China | 3 |

| CMM | STRATO-Apex 9106 | Japan | 1 |

Why Choose Modest CNC Machining Services

1. Hi-Tech Manufacturing Equipment

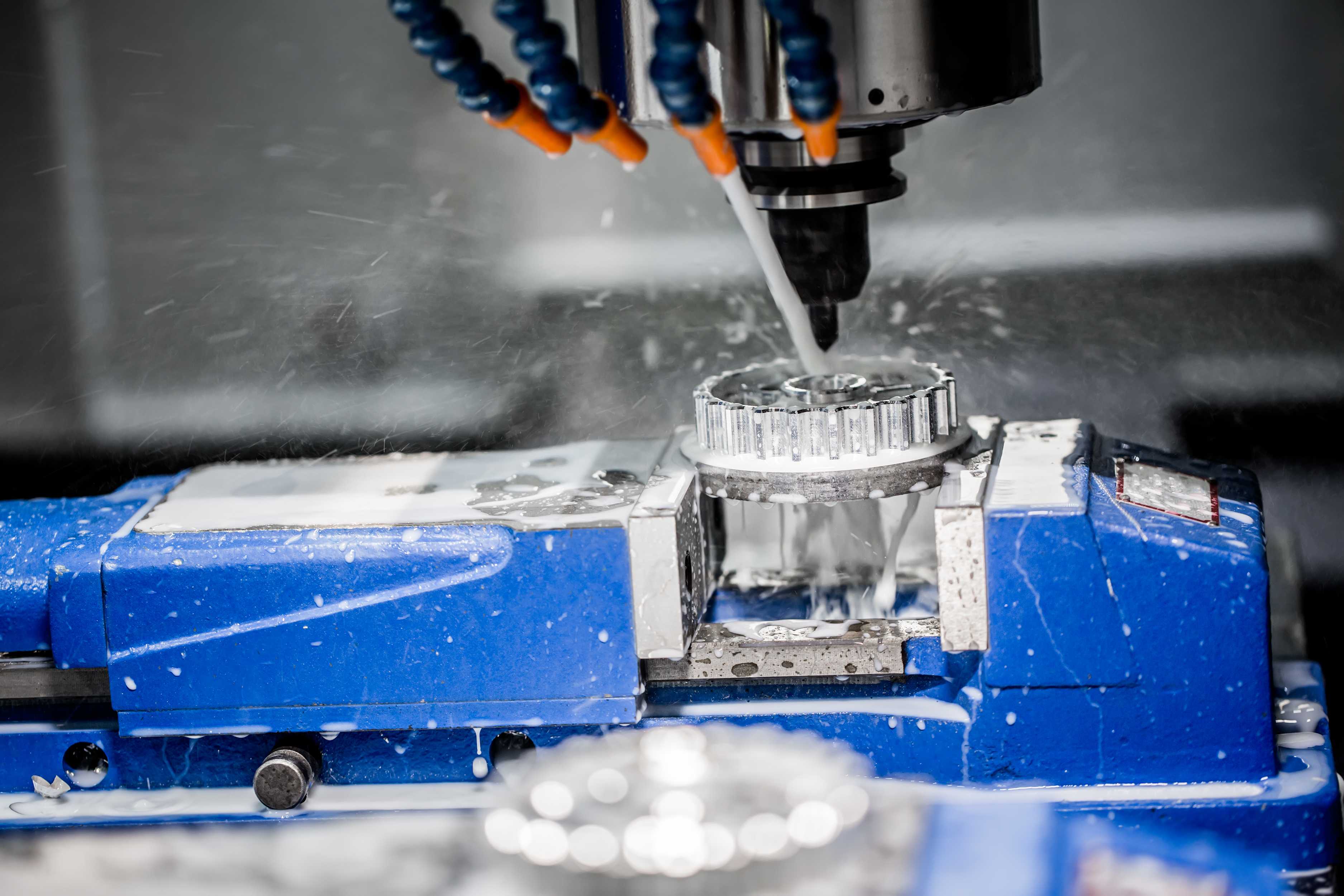

Our core manufacturing equipments are imported from Switzerland and Japan, which can provide customers with tight machining tolerance(±0.01mm).

2. Multiple CNC manufacturing capabilities

In addition to CNC machining, we also specialize in Laser Cutting,Stamping,Diecasting and other metal machining service, so you can obtain a large selection of metal machining service from our trusted team.

3. Strong R&D Strength

We have 10 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China. We can offer the most professional CNC design and CNC engineering services.

4. Strict Quality Control (ISO 9001: 2015)

We have professional quality inspection personnel & equipments, according to the international standards to your products to test, and issue a detailed test report for customers' CNC machining parts.

5. OEM & ODM Acceptable

Customized sizes and shapes are available. Welcome to share your 2D or 3D drawings of your CNC machining parts with us, let's work together to make life more creative.

What Is CNC Machining Service & How CNC Machining Works

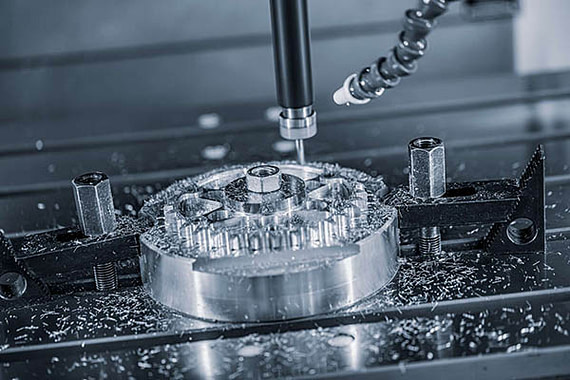

CNC machining is a subtractive manufacturing process that rapidly removes material from metal or plastic blocks to produce precision parts with tight tolerances.

CNC Machining is best suited as a secondary or finishing process for an already machined workpiece, providing definition to or producing the part's features, such as holes, slots, and threads. However, the process is also used to shape a stock piece of material from start to finish. In both cases, the milling process gradually removes material to form the desired shape and form of the part. First, the tool cuts small pieces off the workpiece to form the approximate shape and form. Then, the workpiece undergoes the milling process at much higher accuracy and with greater precision to finish the part with its exact features and specifications. Typically, a completed part requires several machining passes to achieve the desired precision and tolerances. For more geometrically complex parts, multiple machine setups may be required to complete the fabrication process.

CNC Machining Materials – Materials Used for CNC Machining: Available materials for CNC Machining

| Aluminum | Stainless steel | Mild, Alloy & Tool steel | Plastics | Reinforced plastic | Other material |

| 6061-T6 | 303 | Mild steel 1018 | ABS | Garolite G-10 Garolite G-10 Garolite G-10 Garolite G-10 | Brass C360 Brass C360 |

| 6082 | 304 | Mild steel 1045 | Polypropylene | Polypropylene (PP) 30%GF | Copper C101 Copper C101 |

| 7075-T6 | 316L | Mild steel A36 | Nylon 6 | Nylon 30%GF Nylon 30%GF Nylon 30%GF | Copper C110 |

| 5083 | 2205 Duplex | Alloy steel 4140 | Delrin(POM-H) | FR4 | Titanium Grade 1 |

| 5052 | 17-4 | Alloy steel 4340 | Acetal(POM-C) | Titanium Grade 2 | |

| 2014 | 15-5 | Tool steel O1 | PVC | Invar | |

| 2017 | 416 | Tool steel A2 | HDPE | Inconel 718 Inconel 718 | |

| 6063 | 420 | Tool steel A3 | UHMWPE | Magnesium AZ31B Magnesium AZ31B | |

| 7050 | 430 | Tool steel D2 | Polycarbonate | ||

| A380 | 440C | Tool steel S7 | PET | ||

| MIC 6 | 301 | Tool steel H13 | PTFE(Teflon) |

Applications of CNC Machining Services and Parts

Modest CNC Machining Surface Finishes

Here is a wide selection of metal surface finishing services at your choice for the machined CNC machining parts to improve the parts appearance, surface smoothness, corrosion resistance, and other characteristics:

① As machined(standard): ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part.

② Smoothed: Parts are machined at a lower feed rate in order to achieve a surface roughness of ~62.5 RA µin (1.6 RA µm). Surface roughness can be decreased up to ~32 RA µin (0.8RAµm) upon request.

③ Bead Blasted: Bead blasting adds a uniform matte or satin surface finish on a machined part, removing all tool marks. Mainly used for aesthetic purposes.

④ Anodized Clear or Color: Anodizing adds a thin, hard, non-conductive ceramic coating on the surface of aluminum parts, increasing their corrosion and wear resistance. Available in a variety of colors.

⑤ Anodized Hardcoat: Hardcoat anodizing produces a thicker ceramic coating providing excellent corrosion and wear resistance. for functional applications.

⑥ Powder Coated: Powder coating adds a thin layer of strong, wear and corrosion resistant protective polymer paint on the surface of a part. Available in a large range of colors.

⑦ Electropolished: Electropolishing is an electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface surface roughness.

⑧ Black oxide: Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection.

⑨ Chromate conversion coating (Alodine/Chemfilm): Chromate conversion coating is used to increase the corrosion resistance of metal alloys while maintaining their conductive properties.

⑩ Brushing: Brushing is produced by polishing the metal with grit resulting in a unidirectional satin finish.

CATEGORIES

LATEST NEWS

Contact

CONTACT USName: Mr Andy Chen

Mobile:+86 13401201412

Tel:+86 13401201412

Whatsapp:+86 13401201412

Email:inquiry@metalmachining.com.cn

Add:Building 2, Oujing Huadu, Jichuan Street,Taixing City, Jiangsu Province, China 225400