Quality Control

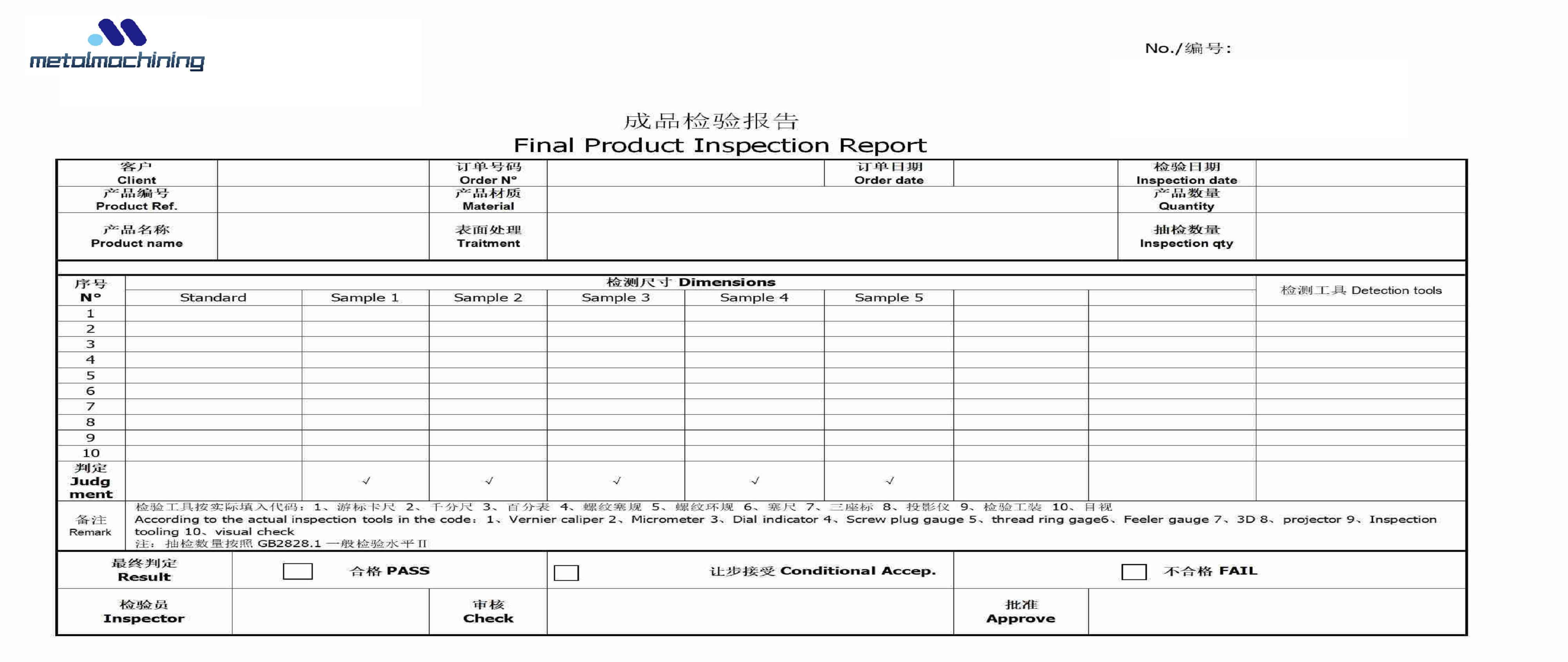

Quality inspection process

①:Modest inspection center is equipped with CMM detectors from ZEISS and HEXAGON, projector,altitude instrument from Mitutoyo,ultrasonic fault detector,vernier caliper,

micrometer,all specifications plug gauge, Go-No-Go gauge etc...

Our inspection center will mainly carry out comprehensive testing for high-precision parts, rather than sampling testing to ensure each part meet customer's requirement.

②:Other low-precision parts will be sampled and tested by the inspection center, and then comprehensively tested by our automatic testing instruments imported from Japan.

We always practice that all parts must be tested before leaving the factory.

③:After all the parts have passed physical and chemical testing, our packaging personnel will check the appearance of the products at the same time of packaging to remove the products with poor appearance.

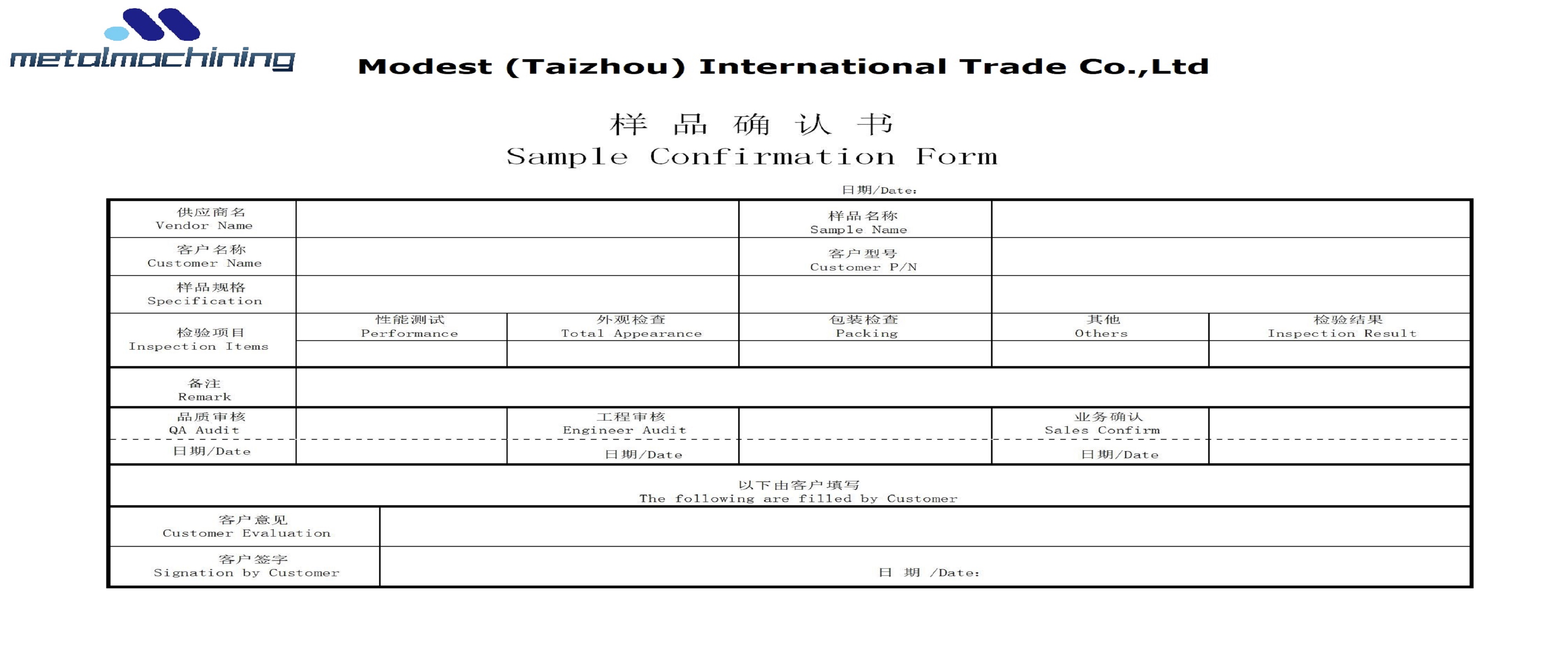

Sample Confirmation

After we get your sample order, we will complete the sample production in the shortest time and issue the sample test report. After our quality inspection department passes the sample test, we will send the sample confirmation letter together with the sample to the customer, and the customer need sign and send it back to us before mass production.

LATEST NEWS

Contact

CONTACT USName: Mr Andy Chen

Mobile:+86 13401201412

Tel:+86 13401201412

Whatsapp:+86 13401201412

Email:inquiry@metalmachining.com.cn

Add:Building 2, Oujing Huadu, Jichuan Street,Taixing City, Jiangsu Province, China 225400